When it comes to choosing the right commercial bone saw for your kitchen, efficiency and durability are key. With a range of powerful options available in 2026, understanding the features and specifications of each model can make all the difference in your meat processing tasks. Whether you’re a butcher or run a restaurant, the right saw can enhance your workflow. Curious about which models stand out this year and what factors to contemplate?

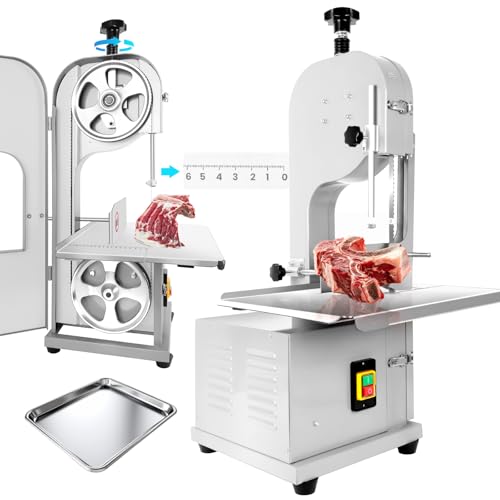

Commercial Electric Meat Bandsaw, 1500W Stainless Steel Countertop Bone Sawing Machine

If you’re running a restaurant or a meat processing plant, the Commercial Electric Meat Bandsaw, with its powerful 1500W motor, is the perfect tool for your cutting needs. This stainless steel countertop machine efficiently cuts through hard bones and frozen meat, handling up to 300 kg/h. Its adjustable cutting thickness, ranging from 0.16 to 7.9 inches, guarantees precise results every time. Constructed from durable aluminum alloy and reinforced stainless steel, it’s designed for long-lasting use. With safety features like a single-button switch and protective plate, you can operate it confidently while achieving excellent cutting results for any meat type.

Best For: The Commercial Electric Meat Bandsaw is best for restaurants, meat processing plants, and any business that requires efficient and precise cutting of various types of meat and bones.

Pros:

- Powerful 1500W motor allows for efficient cutting of hard bones and frozen meat, handling up to 300 kg/h.

- Adjustable cutting thickness from 0.16 to 7.9 inches ensures precise and customizable cuts for different meat types.

- Durable construction with stainless steel and aluminum alloy provides long-lasting performance and resistance to wear and rust.

Cons:

- The machine may require a dedicated space due to its countertop dimensions of 19.3″ x 15″.

- Initial setup and blade installation may be challenging for inexperienced users.

- Regular maintenance and blade replacement are necessary to ensure optimal performance and safety.

VEVOR Commercial Electric Meat Bandsaw

The VEVOR Commercial Electric Meat Bandsaw stands out as an essential tool for high-demand environments like restaurants and meat processing plants, thanks to its powerful 2200W motor that effortlessly cuts through hard bones and frozen meat. With cutting efficiency reaching up to 3307 lbs/H, you’ll save time on tough jobs. Its stainless steel worktable features scale lines for precise thickness adjustments, accommodating everything from thin ham slices to thick bone chunks. Built from durable aluminum alloy and reinforced stainless steel, this bandsaw is wear-resistant and includes six sharp blades, ensuring versatility without rusting. Safety features make operation a breeze.

Best For: The VEVOR Commercial Electric Meat Bandsaw is best for restaurants, meat franchise stores, supermarkets, and meat processing facilities that require heavy-duty cutting capabilities.

Pros:

- High cutting efficiency of up to 3307 lbs/H, saving time on demanding jobs.

- Adjustable thickness settings for precise cutting of various meat types and sizes.

- Durable construction from aluminum alloy and stainless steel, ensuring long-lasting use without rust.

Cons:

- Bulky design may require significant counter space in smaller kitchens.

- Initial cost may be high for small businesses or individual users.

- Requires regular maintenance to ensure optimal performance and longevity.

Commercial Electric Meat and Bone Band Saw Machine

Designed for high-volume meat processing, the Commercial Electric Meat and Bone Band Saw Machine stands out with its powerful 1500W motor, enabling cutting efficiency of up to 670 lbs per hour. Its spacious worktable measures 19.3″ x 19.7″, accommodating various ingredients like ribs, steaks, and frozen fish. With a cutting thickness range of 0.04-7.09 inches, this machine excels in precision thanks to its strong motor and sharp blades. Made from rustproof aluminum and food-grade stainless steel, it’s easy to clean and maintain. Enjoy effortless operation while ensuring safety with its rounded design and included maintenance tools.

Best For: Commercial meat processing plants, slaughterhouses, supermarkets, restaurants, and home chefs looking for efficient and precise meat cutting solutions.

Pros:

- Powerful 1500W motor allows for high cutting efficiency of up to 670 lbs/hour.

- Made from durable, rustproof aluminum and food-grade stainless steel for longevity and easy cleaning.

- Versatile cutting thickness range of 0.04-7.09 inches accommodates various types of meat and bones.

Cons:

- Requires a maximum operation time of 2 hours followed by a 30-minute cooldown, which may limit continuous usage.

- Caution is necessary due to the sharp saw blade during operation and cleaning, posing safety risks.

- The need for assembly upon delivery may be inconvenient for some users.

ROVSUN 750W Electric Bone Saw Machine

For busy kitchens and processing plants, the ROVSUN 750W Electric Bone Saw Machine stands out with its powerful 750W pure copper motor, effortlessly slicing through up to 661 pounds of bones per hour. You’ll appreciate its adjustable cutting thickness, ranging from 0.16 to 7.9 inches, allowing precise cuts for various needs. The six included saw blades guarantee versatility, while the food-grade stainless steel construction assures durability and hygiene. Safety features like the emergency button and wider meat pusher enhance your peace of mind. With its ample workbench and anti-slip feet, this machine combines efficiency and stability for all your cutting tasks.

Best For: The ROVSUN 750W Electric Bone Saw Machine is best for restaurants, meat stores, supermarkets, processing plants, and slaughterhouses that require efficient bone cutting.

Pros:

- Powerful 750W motor allows for cutting up to 661 lbs of bones per hour.

- Adjustable cutting thickness from 0.16 to 7.9 inches for versatile use.

- Made of food-grade stainless steel for durability and hygiene.

Cons:

- Requires a dedicated space due to its workbench dimensions of 18.5 x 12.4 inches.

- May be too powerful for small home kitchens or occasional use.

- Initial setup and adjustment may require some technical knowledge.

Weston Butcher Meat and Bone Saw with 16 Inch Stainless Steel Blade

If you’re looking for a reliable tool to tackle large cuts of meat, the Weston Butcher Meat and Bone Saw with its 16-inch stainless steel blade stands out as an excellent choice. This saw excels at precision cutting, easily slicing through muscle, sinew, and bone, perfect for breaking down large pieces into manageable sizes. Its ergonomic handle minimizes fatigue, ensuring comfortable use during extended butchering sessions. Plus, the trigger lock system maintains ideal blade tension for consistent performance, making it perfect for processing large game. With its sturdy construction, this saw promises durability and efficiency for your meat processing needs.

Best For: The Weston Butcher Meat and Bone Saw is best for hunters, butchers, and home cooks looking to efficiently process large cuts of meat.

Pros:

- Durable 16-inch stainless steel blade designed for precision cutting through meat and bone.

- Ergonomic handle reduces fatigue, allowing for comfortable use during long butchering sessions.

- Trigger lock system ensures consistent blade tension for optimal performance.

Cons:

- The size of the saw may be cumbersome for small kitchen spaces.

- Maintenance may be required to keep the blade corrosion-resistant.

- Not suitable for smaller cuts of meat, as it is designed for larger processing tasks.

KWS B-210 Commercial Electric Meat Band Saw Machine

The KWS B-210 Commercial Electric Meat Band Saw Machine stands out as an exceptional choice for butchers and food service professionals seeking efficiency and precision. Its powerful 110V 1900W motor and high-speed stainless steel blade deliver quick, clean cuts with adjustable thickness up to 6 inches. Constructed from durable, corrosion-resistant materials, it features a spacious stainless steel worktable for accurate measurements. Safety is prioritized with an emergency stop button and a meat pusher for secure handling. Maintenance is a breeze, thanks to its tool-free disassembly and a built-in blade tensioning system, ensuring minimal downtime for your busy kitchen.

Best For: The KWS B-210 Commercial Electric Meat Band Saw Machine is best for butchers and food service professionals who require efficient and precise meat cutting solutions.

Pros:

- Powerful 1900W motor allows for quick and clean cuts.

- Durable construction with corrosion-resistant materials ensures longevity.

- Easy maintenance with tool-free disassembly and a built-in blade tensioning system.

Cons:

- Requires a 110V outlet, which may limit portability.

- Initial cost may be higher compared to manual saws.

- Larger size may require ample workspace for setup and operation.

VEVOR Band Saw Blade, 5 PCS Meat Bandsaw Blades for Replacement

Crafted from high-strength 65Mn carbon steel, the VEVOR Band Saw Blade set is an essential choice for commercial kitchens, butcher shops, and food processing factories looking to enhance their cutting performance. Each pack includes five durable blades measuring 65 inches long, 0.6 inches wide, and 0.02 inches thick. With a hardness of 64 HRC for the saw teeth, these blades deliver exceptional cutting efficiency. The 3 TPI design guarantees smooth, flat cuts with minimal meat loss, making them perfect for cutting frozen meat, fish, and hard bones. Compatibility with various commercial saw machines makes them a reliable choice for your kitchen.

Best For: The VEVOR Band Saw Blade set is best for commercial kitchens, butcher shops, and food processing factories that require efficient and reliable meat cutting solutions.

Pros:

- Durable construction from high-strength 65Mn carbon steel enhances longevity and cutting performance.

- Designed with 3 TPI for smooth, flat cuts, minimizing meat loss during processing.

- Compatible with various commercial meat bone saw machines, making it versatile for different settings.

Cons:

- May not be suitable for non-commercial use or smaller kitchens due to their size and industrial design.

- Requires proper maintenance to ensure longevity and performance, which may be demanding for some users.

- Limited to specific applications, primarily for cutting meat and bones, which may not be ideal for all cutting needs.

2500W Commercial Electric Meat Bandsaw

Designed for high-volume meat processing, the 2500W Commercial Electric Meat Bandsaw stands out with its powerful motor and exceptional cutting efficiency. You can easily cut through large bones, from lamb legs to beef femurs, with adjustable thickness up to 7.9 inches. This bandsaw boasts a reinforced stainless steel build, ensuring durability and resistance to wear. It operates smoothly without jamming, handling 1900-2400 lbs per hour. Safety features like a one-button switch and a stainless steel pusher plate keep you protected. Ideal for restaurants, supermarkets, and processing plants, this saw is a must-have for efficient meat preparation.

Best For: The 2500W Commercial Electric Meat Bandsaw is best for restaurants, meat processing plants, and supermarkets that require high-efficiency meat cutting for large volumes.

Pros:

- High cutting efficiency of 1900-2400 lbs per hour, perfect for large-scale operations.

- Durable stainless steel construction ensures longevity and resistance to wear and rust.

- Adjustable cutting thickness allows for precision in cutting various types of meat and bones.

Cons:

- Initial cost may be high, making it a significant investment for smaller operations.

- Requires regular maintenance to ensure optimal performance and longevity.

- Bulky size may require ample workspace, limiting placement options in smaller facilities.

Meat Bandsaw Machine, Commercial Electric Bone Saw

For butchers and small meat processing facilities looking for efficiency, the Meat Bandsaw Machine stands out as a top choice in the commercial electric bone saw category. With its powerful 2000W motor, it delivers strong torque for heavy-duty cutting of meat and bones. You’ll appreciate the wide cutting thickness range, accommodating various slicing needs. Safety’s a priority, thanks to the stainless steel push rod that keeps your hands at a safe distance from the blade. Built with durable stainless steel, it’s easy to clean and maintain, making it perfect for daily use in butcher shops and processing facilities.

Best For: Butchers, home butchers, and small meat processing facilities seeking a reliable and efficient solution for cutting meat and bones.

Pros:

- Powerful 2000W motor provides strong torque for heavy-duty cutting.

- Wide cutting thickness range of 0.04–7.8 inches accommodates various slicing needs.

- Durable stainless steel construction ensures longevity and easy maintenance.

Cons:

- May require a significant investment for small-scale users.

- The machine’s weight could make it less portable for some users.

- Limited to meat and bone cutting, not versatile for other food items.

Bone Saw for Butchering, 550w Commercial Bandsaw Machine

If you’re in the butchery or catering business, the 550w Commercial Bandsaw Machine is a game-changer. This heavy-duty electric meat saw effortlessly cuts through bones up to 5.7 inches thick, ensuring precision with its adjustable thickness feature. Its commercial-grade stainless steel work surface withstands heavy use, while six durable carbon steel blades keep cutting efficiently. Safety’s a priority too, with a multi-layer architecture and an anti-slip base that enhance reliability. Whether you’re processing beef femurs, pork ribs, or frozen fish fillets, this versatile bandsaw delivers excellent performance, making portion control simple and effective in your kitchen.

Best For: This product is best for butchers, caterers, and commercial kitchens that require efficient and precise meat cutting capabilities.

Pros:

- Precision cutting with adjustable thickness from 0.39 to 5.7 inches for uniform portions.

- Durable construction with a commercial-grade stainless steel work surface and six carbon steel blades for long-lasting performance.

- Safety features including a waterproof switch and anti-slip base enhance operational reliability.

Cons:

- Heavyweight may make it difficult to move or reposition in smaller kitchens.

- Requires regular maintenance to keep blades sharp and ensure optimal performance.

- Initial cost may be high for small businesses or home users.

Factors to Consider When Choosing a Commercial Bone Saw

When choosing a commercial bone saw, you need to think about several key factors. The power and motor strength, cutting thickness range, and overall durability will greatly impact your efficiency. Plus, don’t overlook the importance of safety features and ease of maintenance to keep your operation running smoothly.

Power and Motor Strength

Choosing the right power and motor strength is essential in selecting a commercial bone saw that meets your operational needs. Typically measured in watts, stronger models range from 750W to 2500W, offering varying cutting efficiencies. For high-volume meat processing, a motor with 2200W or 2500W can achieve up to 3307 lbs/hour, ensuring you get the job done quickly. Look for motors with pure copper construction for durability, as they reduce overheating risks during continuous operation. Additionally, consider saws with precision gear designs and stainless steel blades, which facilitate smooth operation and reduce cutting effort. A powerful motor paired with quality components will enhance your efficiency and performance in any kitchen setting.

Cutting Thickness Range

Power and motor strength play a considerable role in your selection process, but the cutting thickness range of a commercial bone saw is equally important. Typically ranging from 0.04 inches to 8.7 inches, this range allows you to tackle various meat and bone types effectively. Look for models with adjustable thickness settings, as they enable precise cuts—from thin slices of prosciutto to thick chunks of beef femur. Most saws handle thicknesses from 0.16 inches to over 7.9 inches, offering the flexibility needed for diverse butchering tasks. A wider cutting thickness range enhances your ability to process larger bones and tougher materials efficiently. Choosing a saw with adjustable features can considerably boost your operational efficiency in a commercial meat processing environment.

Material and Durability

While selecting a commercial bone saw, the material and durability are crucial factors that can impact your operations greatly. Look for saws constructed from high-quality materials like food-grade stainless steel and aluminum alloy, as these offer corrosion resistance and long-term durability. A stainless steel work surface guarantees compliance with health regulations and simplifies cleaning. Additionally, choose saws made from wear-resistant and scratch-resistant materials to enhance longevity, even with frequent use. Reinforced structures are essential for heavy-duty operations, especially when processing large cuts of meat and bone. Finally, opt for blades made from high-strength carbon steel, which maintain sharpness through rigorous use on tough bones and frozen products, markedly improving cutting efficiency.

Safety Features Included

When it comes to selecting a commercial bone saw, prioritizing safety features is vital for protecting both operators and the workspace. Look for machines equipped with a one-button switch for quick and safe operation, allowing you to start and stop effortlessly. Safety mechanisms, such as a stainless steel pusher plate, are essential for keeping your hands away from the blade during use. Models with emergency stop buttons and waterproof on/off switches enhance operational safety in case of accidents. Additionally, choose saws with stabilizers and anti-slip feet to reduce the risk of accidents while cutting. Finally, designs that incorporate locking mechanisms or calibrated scales guarantee consistent cutting thickness, helping to prevent slips and injuries while you work.

Ease of Maintenance

Selecting a commercial bone saw that’s easy to maintain can save you time and hassle in the long run. Look for models with straightforward blade removal mechanisms, allowing you to clean and maintain the saw quickly. A sealed motor design is beneficial, as it enables rinsing with water without damaging electrical components. Stainless steel surfaces are preferable, resisting rust and corrosion, which enhances longevity and ease of cleaning. Additionally, choose units with accessible components like the saw blade and waste tray for simple upkeep. Regular maintenance should involve tools-free disassembly options for parts that need cleaning or replacement, minimizing downtime and ensuring your kitchen runs smoothly. Prioritize these features to keep your bone saw in top shape.